The evolution of direct fastening into plastics

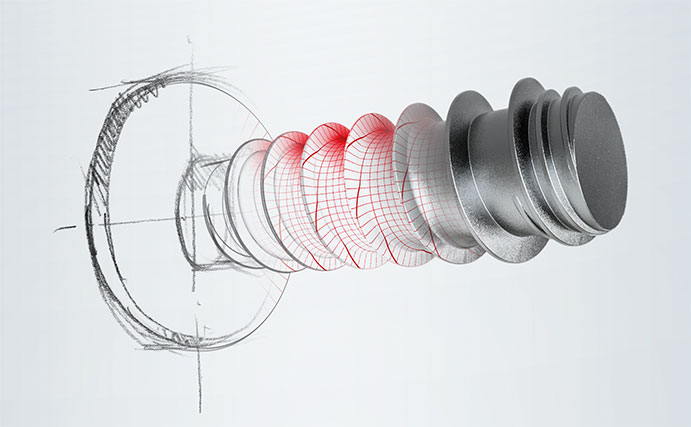

EJOT’s EVO PT® screw sets new standards in direct fastening into plastics. It combines excellent joining properties with highly flexible assembly options. Due to a unique tool, a pre-calculation and verification system can be obtained already at an early stage of development. Corresponding predictions may even contain operation conditions.Due to their exceptional high strength, modern engineering plastics are used in an increasing number of market segments. Possible application fields can be found in all industrial sectors. Thermoplastic structural materials are often used in automotive industry, where components are designed for elevated temperatures. Accordingly, the joining technology needs to meet these high demands. EJOT as joining specialist has a decade-long expertise in this field and puts the EVO PT® as next evolutionary step of direct fastening into plastics on the market.

The extensive experience in customer project support was used as a valuable knowledge base for the development of this new screw. This fastener combines excellent joining behavior with manufacturing and application engineering knowledge based on physical computer simulation methods.

The EVO PT® effect

Using a consequent geometry analysis of the components, standardization potentials are generated in close cooperation with the customer. So far, to obtain identical installation depths in case of clamping parts having different thicknesses, different screw lengths were necessary. Otherwise, it was not possible to use an identical tightening torque for each joint. The special design of the thread forming zone of the EVO PT® allows to obtain an almost constant installation torque, which is independent from the installation depth. Therefore, identical screw dimensions may be used even in cross-part applications. This reduces the assembly component diversity and contributes to an economical and process reliable manufacturing.

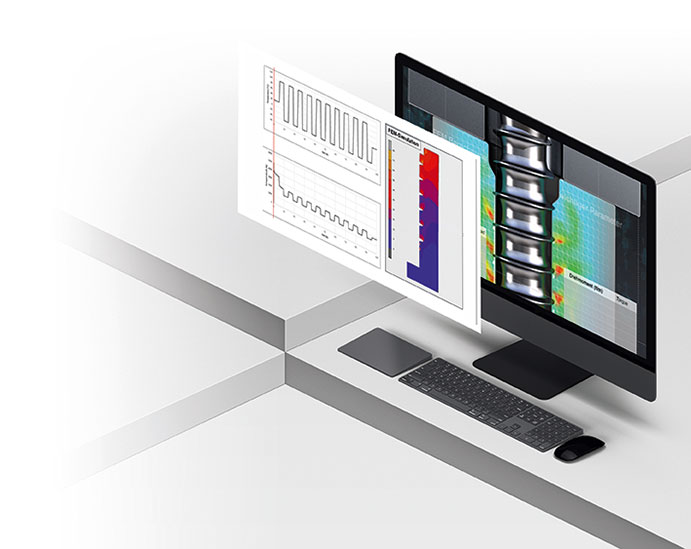

EVO CALC® – the smart calculation service

In case of different screw diameters, the EVO CALC® prognosis program can calculate, if a standardization is possible with screws already in use or if an oversizing or an undersizing exists. This saves valuable development time. Of course, torque values and clamp loads are predicted as well. As special benefit for engineers and developers EVO CALC® also allows to calculate the relaxation behavior of the joint even under the influence of temperature.

Computer Aided Engineering (CAE) for complete assemblies

EJOT offers efficient CAE services to examine and analyze multi-screw joints of complete assemblies. This allows customers to check if the joints will permanently resist the defined loads. A premature detection of potential overloads in the part helps to avoid construction defects in an early stage of development. Therefore, enormous savings of time and costs are possible in case of an early reaction and design change. Using FE analysis, the position of highest stress in the joint can be determined. These results are used for further development of the assembly component.

EVO PT® combines the exceptional joining properties of an excellent screw with novel prognosis tools. These programs allow a precise preview of the design, the assembly process and the behavior of a screw joint. EJOT wants to support not only the demands of engineers, but of all parties which are involved in the complete production chain such as purchasing, production and quality management. This is of importance as each single process influences the overall success of a company.