EJOT ALtracs® Xt

Caratteristiche

-

Panoramica

- Componenti di pressofusione e lavorazione meccanica più economici grazie a tolleranze più ampie

- La progettazione analitica e numerica dei giunti avvitati consente di risparmiare tempo e risorse

- Permette design compatti, leggeri e adatti alla pressofusione dei componenti

CAD & more - Your Online-Service

* To have access to our CAD data, tools and other services, registrarsi qui.

ALtracs® Xt Standards *

Here you can download some of the Standards.

Xt CALC® Prognosis Program *

Xt CALC® enables the calculation of assembly parameters of the ALtracs® Xt screw and provides information on the dimensioning of the self-tapping screw joint in light and non-ferrous metals

CAD & more - Your Online Service Area

Unfortunately you currently have no authorization to use "CAD & more".

Unfortunately, this data can not be provided to you without the consent of the confidentiality agreement.

Your request will be manually verified, this can take 1 to 3 business days.

-

For technical questions please contact +39 049 986 9023 INDUSTRY Division

Problems with your access? Mail to: service-industrie@ejot.com

Grant Access to CAD Data

Unfortunately you currently have no authorization to use "CAD & more".

Apply for access to CAD data.

-

For technical questions please contact +39 049 986 9023 INDUSTRY Division

Problems with your access? Mail to: service-industrie@ejot.com

Thank you!

Your request will be manually verified, this may take 1 to 3 business days.

You will receive an e-mail as soon as your access for "CAD & more" has been activated.

Thank you for your patience.

-

For technical questions please contact +39 049 986 9023 INDUSTRY Division

Problems with your access? Mail to: service-industrie@ejot.com

Confirm CAD data renewal

In the e-mail sent by us you will find the link to verify your account, please click on it.

If you do not receive an e-mail within a few minutes, please check your spam folder.

-

For technical questions please contact +39 049 986 9023 INDUSTRY Division

Problems with your access? Mail to: service-industrie@ejot.com

Can not be renewed

Please contact our customer care

-

For technical questions please contact +39 049 986 9023 INDUSTRY Division

Problems with your access? Mail to: service-industrie@ejot.com

Can not process your request for CAD

Please contact our customer care

-

For technical questions please contact +39 049 986 9023 INDUSTRY Division

Problems with your access? Mail to: service-industrie@ejot.com

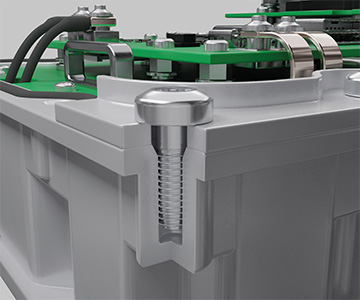

Filettatura nelle leghe leggere senza compromessi

Le viti EJOT ALtracs® Xt sono elementi di fissaggio autoformanti sviluppati per l'uso in leghe leggere e altri metalli non ferrosi con una durezza fino a 140 HB. In passato, l'uso di viti autoformanti per leghe leggere comportava un compromesso tra carico di serraggio e prestazioni di coppia. Alcuni design eccellevano nel carico di serraggio (viti con filettatura circolare), mentre altri ottenevano ottimi risultati nelle prestazioni di coppia (viti con filettatura non circolare). Con ALtracs® Xt, questo compromesso non è più necessario, poiché raggiunge risultati eccellenti in entrambe le specifiche.

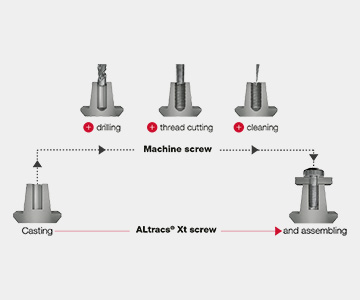

Economica

Grazie all'eliminazione di vari passaggi di lavorazione, l'uso di elementi di fissaggio autoformanti offre un grande potenziale di risparmio economico. Con ALtracs® Xt, è possibile assemblare un giunto avvitato direttamente su una geometria stampata senza ulteriori fasi di lavorazione (ad es. foratura, filettatura). Grazie al suo design intelligente della filettatura, ALtracs® Xt è in grado di gestire le tolleranze del processo di fusione, garantendo affidabilità ed elevate prestazioni meccaniche anche in condizioni difficili.

Intelligente

ALtracs® Xt offre la possibilità di pre-progettare il giunto tramite il software di calcolo Xt CALC®. Questo software consente di calcolare tutti i parametri rilevanti del processo e del giunto (ad es. coppie, livelli di carico, intercettazione di rotture. ecc..). Xt CALC® consente quindi un design orientato al carico di serraggio, basato sulla norma VDI 2230.

Inoltre, EJOT offre una vasta gamma di servizi di ingegneria personalizzati. Con un focus sull'influenza dell'elemento di fissaggio sul componente completo, sono possibili analisi del rilassamento del carico di serraggio o della tenuta stessa in fase di esercizio.

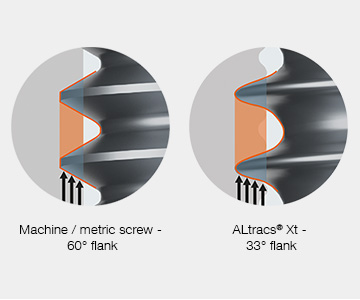

Compatta

Grazie al suo specifico design della filettatura per l'uso nelle leghe leggere, ALtracs® Xt raggiunge caratteristiche uniche. La sezione trasversale circolare della filettatura crea il massimo ingaggio in ciascun passo di filettatura. Inoltre, l'angolo di fianco ridotto di 33° (rispetto ai 60° di un fissaggio standard) consente ad ALtracs® Xt di rinforzare geometricamente la parte in lega leggera della filettatura.

Queste due caratteristiche permettono ad ALtracs® Xt di generare giunti ad alta resistenza con un minimo ingombro in termini di diametro e lunghezza della sede da filettare.

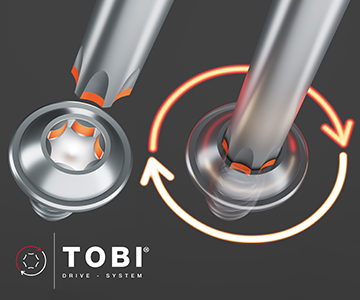

TOBI® Drive-System - L'impronta innovativa ad alte prestazioni

- Presa sicura senza punte magnetiche o sistemi a vuoto

- Allineamento assiale della vite e dell'inserto

- Maggiore durata degli inserti grazie all'area di contatto ampliata (fino a 70 volte superiore)

- Retrocompatibilità con inserti TORX esalobati standard